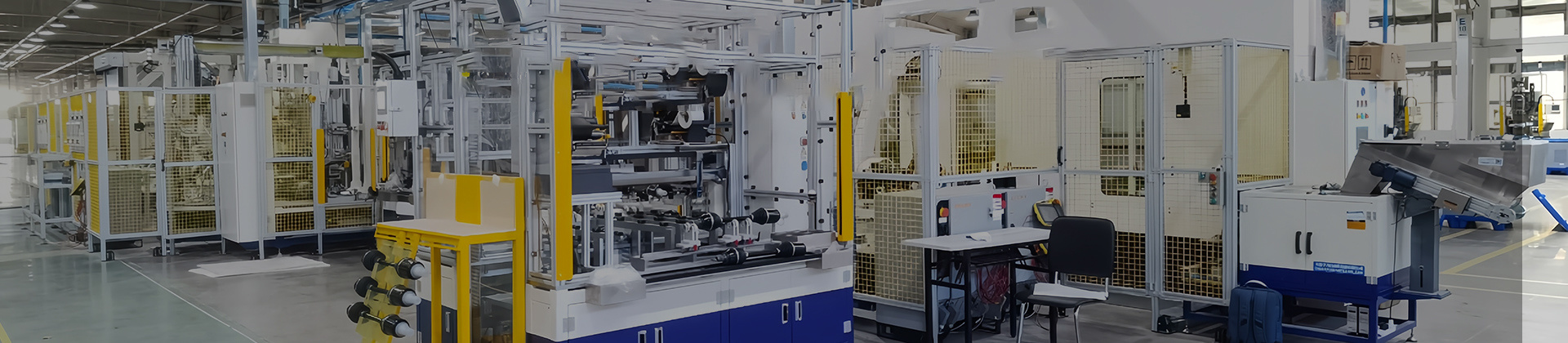

Fully automatic pass-through lead screw cleaning machine

Key words:

Large single tank ultrasonic cleaning machine | Slider cleaning equipment | Precision guide rail cleaning equipment | Rotary spray cleaning machine

Product Classification:

一、Equipment Overview

二、Core Functions

(1) Efficient Demagnetization

- The built-in high-performance demagnetization device adopts alternating magnetic field technology to quickly eliminate residual magnetism generated in precision lead screws during processing. By precisely controlling the magnetic field strength and demagnetization time, it ensures that the residual magnetism of the lead screw meets industry standards, avoiding metal debris adsorption due to residual magnetism, which may affect subsequent assembly and service performance.

(2) Deep Cleaning

- Multi-directional Spray System: Multiple groups of high-pressure spray nozzles are arranged inside the equipment to form a three-dimensional cross-spray network, performing 360° dead-angle-free flushing on the lead screw surface. For stubborn stains such as oil stains and metal powders, it works with special cleaning agents to achieve strong stripping and efficient dissolution.

- Circulating Filtration System: The cleaning solution is recycled after multi-stage filtration, effectively separating impurities and oil stains, prolonging the service life of the cleaning solution, reducing usage costs, and simultaneously minimizing waste liquid discharge.

(3) Rapid Drying

- Hot air circulation drying technology is adopted, generating strong and uniform hot air flow through high-temperature resistant fans and heating devices. During the lead screw transportation process, it quickly evaporates residual surface moisture, avoiding water stain residue and rust risks, and ensuring the workpiece is dry and clean.

三、Automation System

(1) Intelligent Loading and Unloading

- The equipment is equipped with 4-meter-long automatic loading and unloading mechanisms at both ends, which can seamlessly connect with the production line. Through the collaborative work of robotic arms, conveyor belts, and sensors, it realizes automatic grabbing, conveying, and positioning of workpieces, greatly reducing manual operation intensity and errors, and improving production continuity.

(2) Full-automatic Control

- Equipped with a PLC intelligent control system, it supports users to customize cleaning parameters, such as demagnetization time, spray pressure, drying temperature, and conveying speed. The system monitors the equipment operation status in real time, with fault diagnosis and alarm functions to ensure stable and reliable equipment operation.

四、Equipment Advantages

- High-precision Cleaning: Meets the surface cleanliness requirements of precision lead screws, ensuring product processing accuracy and quality stability.

- High Efficiency and Energy Saving: Automated operation reduces manual intervention, and the circulating filtration and hot air recycling design reduces energy consumption and consumable costs.

- Safety and Reliability: The equipment is equipped with multiple safety protection devices, such as leakage protection, overheating protection, emergency stop buttons, etc., to ensure the safety of operators and equipment.

- Convenient Maintenance: Modular design facilitates daily maintenance and repair, and key components use high-quality materials to extend the service life of the equipment.

Product Consulting

If you are interested in our products, please leave your email and get the product quotation for free, thank you!