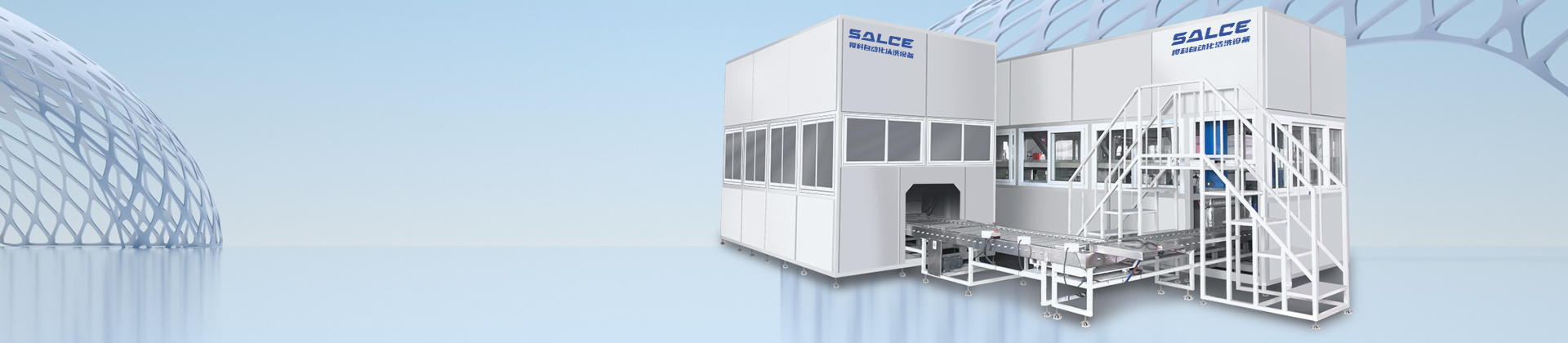

Automatic Online Cleaning Equipment for Guide Rail Laser Marking

Key words:

Large single tank ultrasonic cleaning machine | Slider cleaning equipment | Precision guide rail cleaning equipment | Rotary spray cleaning machine

Product Classification:

Suitable for guide rails, lead screws, and other workpieces with high cleanliness requirements

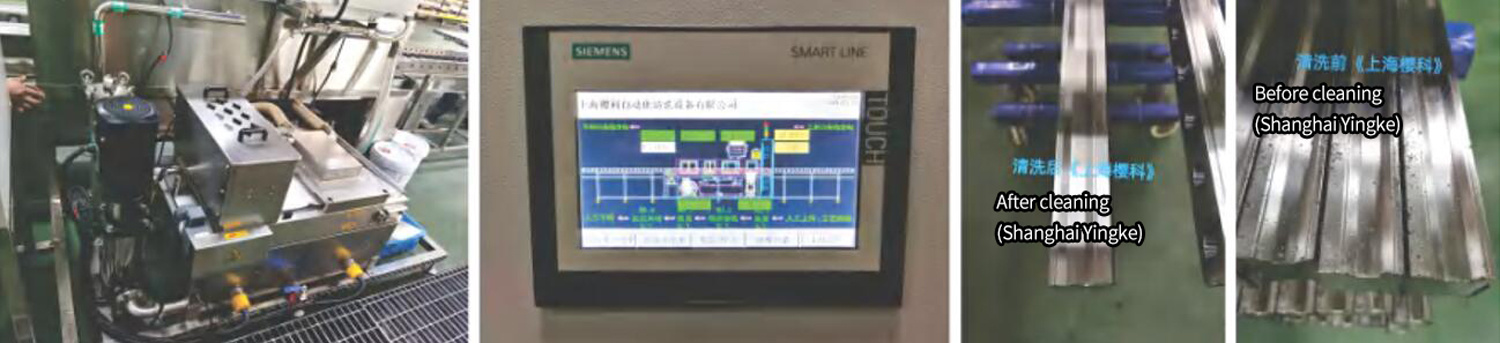

The process zones include spray rough cleaning, spray fine cleaning, spray rinsing, and air knife drying, improving production capacity and meeting various guide rail cleaning requirements.

Loading and unloading are accomplished via gravity rollers/power rollers for cleaning and air knife drying in the cleaning station

Workpieces can be continuously or step-fed (rust-preventive oil spraying can be added)

Main Technical Parameters

Equipment Parameters | SYK-TC2000(Single-stage cleaning) | SYK-TC5000(Three-stage cleaning) |

|---|---|---|

Length*width*height | 2900L*2000W*2500H | 7600*2100*1830 |

Loading and Unloading Height (Approx.) | 1500mm | 870(mm) |

Reservoir Capacity (approx.) | 128(L) | 300L |

Ultrasonic Frequency | / | / |

Cleaning Temperature | 50-70°C | 50-70°C |

Cleaning Pressure | 3-10(bar) | 3-10(bar) |

Average Operating Power (Approx.) | ≈26KW | ≈43KW |

Typical Tools

Product Consulting

If you are interested in our products, please leave your email and get the product quotation for free, thank you!