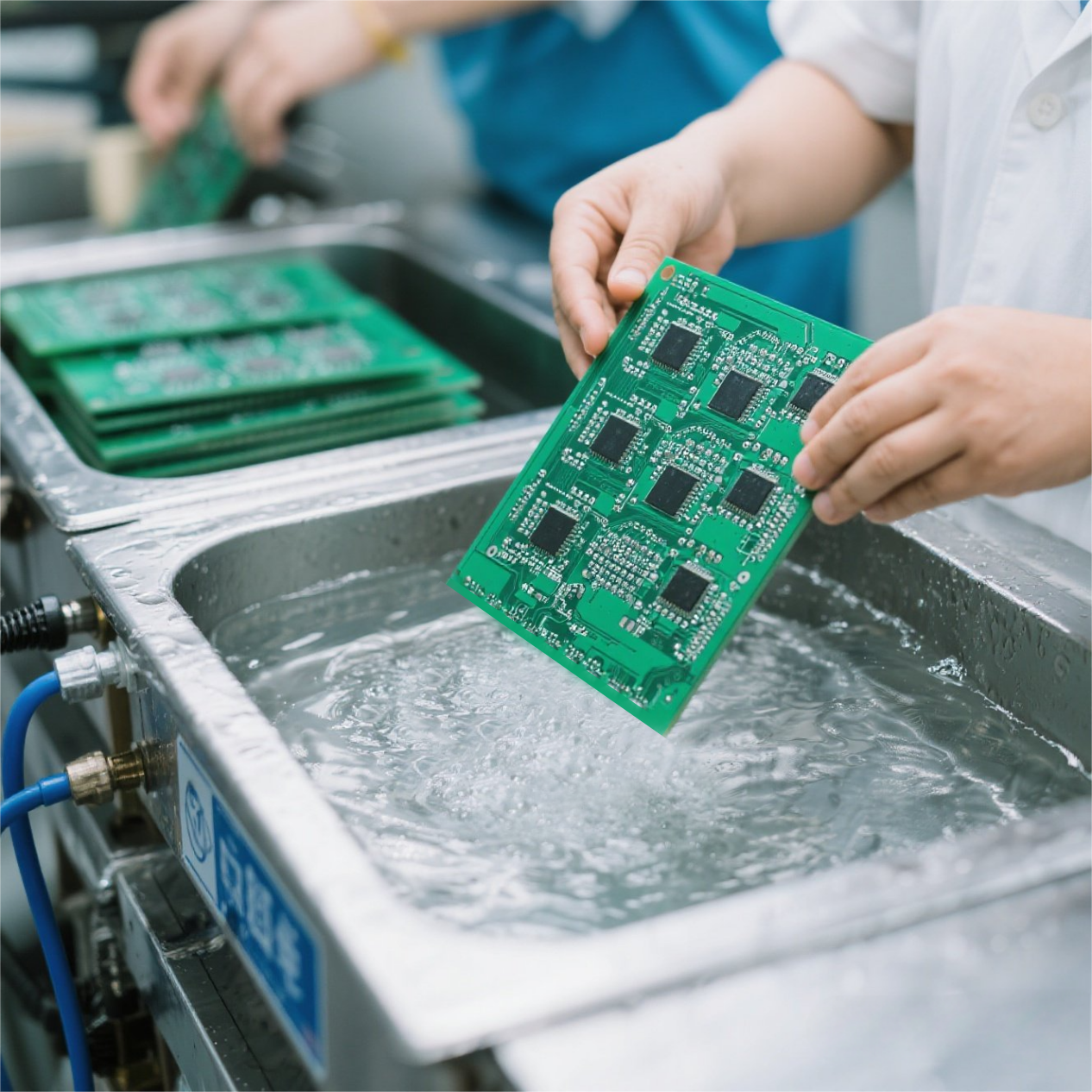

PCB ultrasonic process

Release time:

2025-05-23

Compared to other cleaning methods, ultrasonic cleaning is the perfect choice for cleaning PCBs.

The high cleaning efficiency of ultrasonic cleaners benefits from the penetration and cavitation shock waves generated by the propagation of sound waves in the medium. Therefore, it is easy to clean components with complex shapes, internal cavities, and fine spaces. For general degreasing, rust prevention, and phosphating processes, it only takes two or three minutes to complete under ultrasonic action.

Its speed is several to tens of times faster than traditional methods, and the cleanliness can also reach a high standard. In many occasions with high requirements for product surface quality and productivity, it more prominently shows results that are difficult or impossible to achieve with other processing methods.

Ultrasonic Cleaning Principle

The cleaning of flux residue is mainly accomplished through dissolution. Whether it is rosin, organic acid, or their tin or lead salts, they all have a certain solubility in the cleaning agent. The removal of residues is completed through the process of transferring from the circuit board surface to the cleaning agent.

In the dissolution process, increasing the temperature of the cleaning agent or using a Fuli Electric ultrasonic cleaner and brushing will accelerate the cleaning speed and improve the cleaning effect. A more reliable method is to use ultrasonic cleaning.

Residue Classification. The residues of printed circuit board welding PCBs can be roughly divided into three categories:

1. Particulate contaminants - dust, lint, and solder balls. Solder balls are a welding defect. If the vibration of the circuit board ultrasonic cleaner causes a large number of small solder balls to gather in one place, it may cause a short circuit. Solder balls can be removed by cleaning;

2. Non-polar contaminants - rosin, paraffin wax, and antioxidant oil used in wave soldering, as well as cosmetics or hand sanitizers left by operators.

3. Polar contaminants - halides, acids, and salts.

Key words:

Ultrasonic cleaner,Ultrasonic cleaning of PCB boards,Clean equipment,Industrial cleaning,Shanghai Yingke Automation Cleaning Equipment Co., Ltd.,Fully automatic ultrasonic cleaning machine,Non-standard automated cleaning equipment,Ultrasonic cleaner customization,Principle of ultrasonic cleaner,Industrial ultrasonic cleaner,Ultrasonic cleaning equipment for electronics factories,Industrial cleaning equipment manufacturer,Ultrasonic device,Washing and drying equipment

Large single tank ultrasonic cleaning machine | Slider cleaning equipment | Precision guide rail cleaning equipment | Rotary spray cleaning machine

Related News

2025-05-23

2025-02-26